Complete sets of high voltage parallel connecting capacitor

Product introduction and its application field

High voltage parallel connecting capacitance equipments, herein simply named equipments or products are mainly used in 3~110kV power frequency system, to ensure local equilibrium of reactive power in the system, to improve power factor, adjust voltage of the network, reduce loss of the current lines, improve availability factor of the electrical equipments. The products are widely applied in industries such as power industry, metallurgy, mines, building material and petrochemical industry, machinery and aerospace. The equipments are mainly composed of attachments such as high voltage parallel connecting capacitors, series connecting reactor, s breakers, dis-connectors, ZnO lightning protector, current transformer, frame, enclosure (or cabinet) and connecting. Users can choose indoor or outdoor equipments according to different environment and select switching type devices according to practical operation need of the system.

Design concept

‘Zero’leakage: all insulators of oil-type product inside the capacitor bank generally apply rolling contact casing pipe and no leakage was guaranteed.

Lifelong anti-corrosion: material of enclosure of the attachments is stainless steel. The equipment assembly frame is made of aluminum alloy sections.

It is assembled in building blocks way. It is designed and delivered in a modularized way, and can be immediately used on site.

Product features and progressiveness

Products are full in types: outdoor types, indoor types, fixing types and adjustable volume types, meeting different demands for various users. The products series are complete as they cover all series of voltage grades ranging from 3kv to 110 kv and special products can be customized according to user’s demand for special voltage grades.

Successful supplier of 110kv directly linked products: 110kv directly linked products have been put into application since 2003. Currently, our company has become suppliers who can provide 110kv directly linked products operating the longest time in our country and operating maximally in numbers.

Absorb international advanced technologies: closely follow international technology trend, promote no-fuse capacitor and no-fuse capacitor equipments.

High voltage parallel connecting capacitor equipments are mainly frame type high voltage parallel connecting capacitor equipments and aggregating type high voltage parallel connecting capacitor, the structure and characteristics of them are summarized as below:

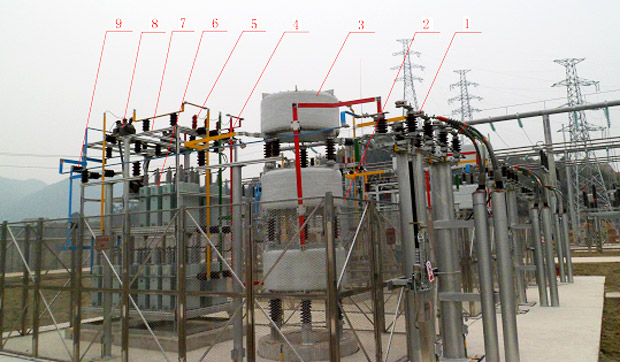

Frame type high voltage capacitor equipments are composed of elements such as disconnecting switch (earthing switch), discharging coil, ZnO lightning protector, series connecting reactor, high voltage parallel connecting capacitor units (current transformer), jet-type fuse, bus, frame (combined cabinet) and enclosures. The frame type equipments can be used both indoor and outdoor. When using indoor, they can be designed in combined cabinet equipment as per the user’s habit. In design process, they can be made in double parallel rows, single row single layer, double layer or three layer structures. And they are characterized with flexible adjustment, simple for erection and maintenance, few oil reserves.

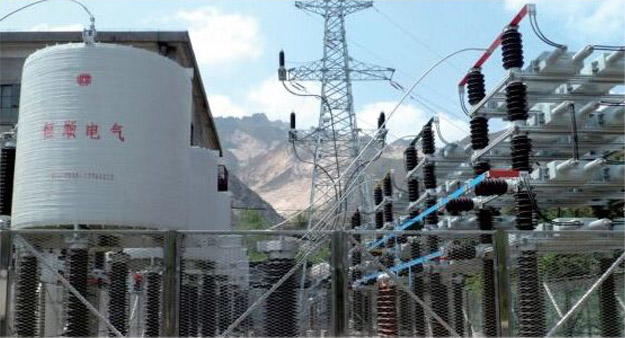

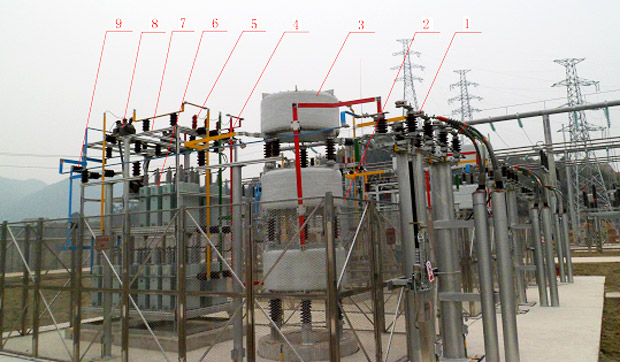

Frame type high voltage capacitor erected outdoor

In the table:1——disconnecting switch (earthing switch);2——enclosures;3——series connecting reactor;4——bus;5——ZnO lightning protector;6——high voltage parallel connecting capacitor units;7——frame (aluminum alloy);8——discharge coil;9——pillar insulator

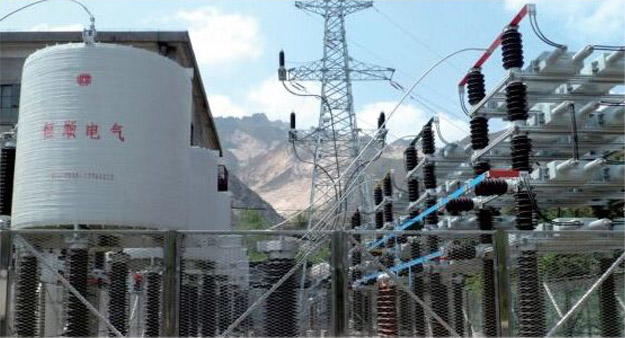

Integrated type high voltage capacitor unit is mainly composed of disconnecting switch (earthing switch), discharge coil, ZnO lightning protector, and series connecting reactor, integrated type high voltage capacitor, bus, frame and enclosures. Integrated type high voltage capacitor unit is generally used outdoor because it is not applicable for indoor usage for consideration of firefighting requirement and its operation is not affected by the environment. It is characterized with full sealing and free for maintenance.

Integrated type high voltage capacitor erected outdoor

In the table:1——series connecting reactor;2——disconnecting switch (earthing switch);3——ZnO lightning protector;4——bus;5——discharge coil;6——pillar insulator;7——current transformer;8——integrated type capacitor;

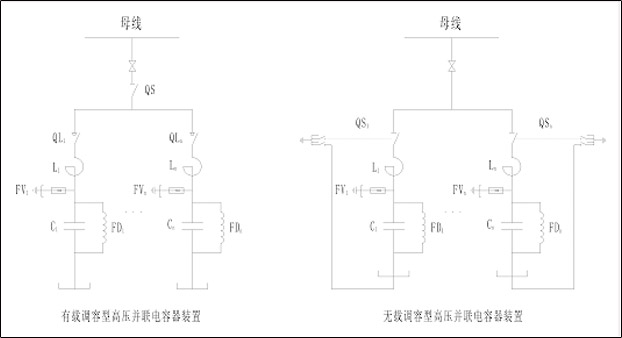

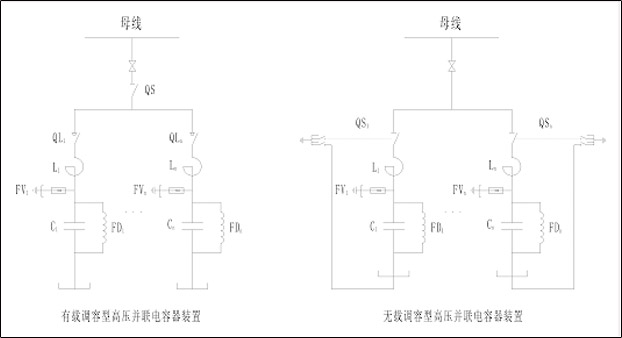

According to practical use requirement of the users, high voltage parallel connecting capacitors can be designed in adjustable volume type unit, including load capacity adjustable type and no load capacity adjustable type. Generally, power system valued below 10kv can achieve load automatic capacity adjustment. The unit can achieve load automatic capacity adjustment through controlling switching of the vacuum contactor or vacuum switches by checking the bus voltage and reactive condition; the capacitor units can be divided into groups as per the requirement of the substations; no load capacity adjustment is divided into power-driven capacity adjustment and manual operated capacity adjustment. No load manual operated capacity adjustment is achieved through disconnecting of different gears of the electric or manual tap switches or different combined switches of the disconnecting switches inside the integrated type capacitor.

Schematic diagram of adjustable volume type high voltage parallel connecting capacitor unit

Primary connection of the device is single-star type or Y-Y connection type. As for power system below 66kv, neutral points in the capacitor unit is ungrounded and its insulation grade is almost the same as the insulation grade in the power system; neutral points in the 110kv capacitor unit shall directly choose effectively grounded or ungrounded as per conditions in different system.

The unit can continuously run under 1.10 times of rated or rated current, and the 1.30 times of root-mean-square value condition except for the transient process. As the maximum practical electric capacity can be amounted to 1.15CN, and the maximum current can come to 1.5IN and those over-current factors are results considering combined action of the harmonic wave and 1.10 UN over voltage.

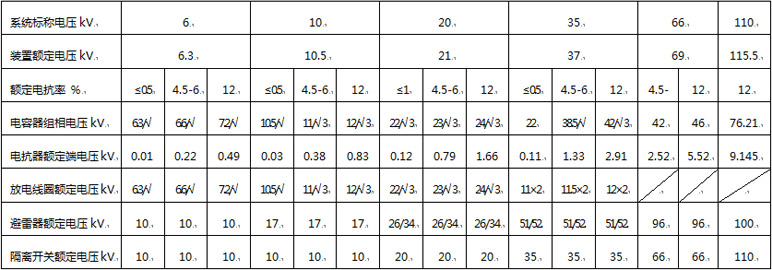

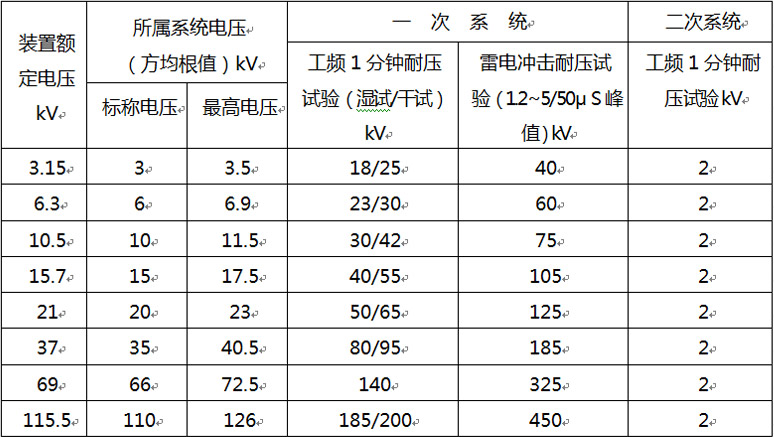

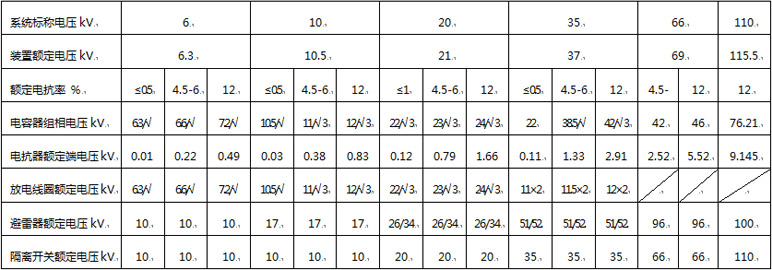

Main attaching electrical parts of the equipment shall meet matching relationship as in the following table.

Rated capacity of the unit is sum of rated capacity all capacitors, deviation of capacity value meet requirements as below: electric capacity of the capacitor bank and rated electric capacity deviation: 0~+5%; the ratio of maximum value and minimum value is no more than 1.02 between any two terminals of three-phase capacitor bank; the ratio of maximum capacity and minimum capacity is no less than 1.01 among each series section in the capacitor set. The ratio of maximum capacity and minimum capacity is no more than 1.005 in different arms.

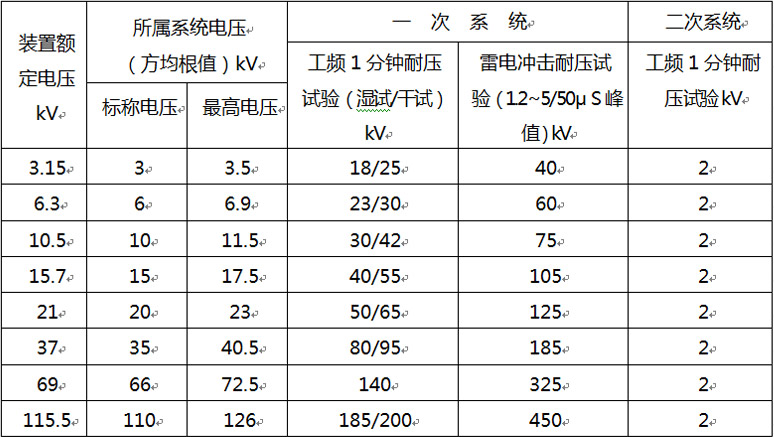

Insulation level of the equipments:

注:二次系统的绝缘电阻不小于2MΩ。